GC-ZKXG30B Stainless steel vacuum capping machine is widely used in food, canned goods, condiments, health products, and other industries. The vacuum capping operation of three (four) rotary tinplate glass bottles can prolong the shelf life of products effectively. Vacuum capping has become the trend of modern bottled food production.

Whatsapp:

+86 17838313979E-mail:

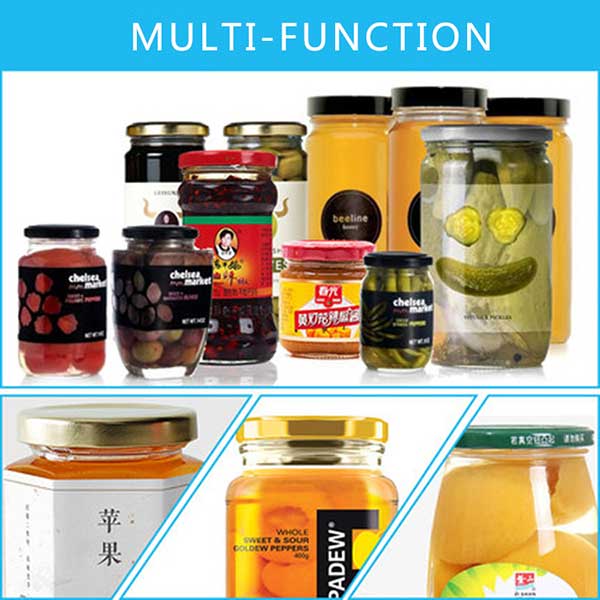

[email protected]Semi automatic vacuum capping machine adopts mechanical, electrical and gas-body design, compact and reasonable structure, the material is high-quality 304 stainless steel and aluminum alloy, which meets GMP requirements.This vacuum capping machine glass jar integrates automatic vacuum capping and capping. Applicable bottle shapes include round, square, various special shapes, etc., with strong applicability ;It is an ideal automatic vacuum capping equipment for glass bottles, which is widely used in various fields such as food and beverage, sauces, condiments, medicine, and health care products.

1. High vacuum, adjustable cap torsion.

2. Vacuum and capping are integrated, with a high degree of automation.

3. GC-ZKXG30B Stainless steel vacuum capping machine applicable bottle type: round bottle, hexagonal bottle, elliptical bottle, and other shaped glass bottles.

Here is the vacuum capping machine youtube video working process in our factory for your reference!!

Rotary Motion Components

Improve twist cap quality and runnability;

microcomputer control

Electronic memory function; electric combination control device;

Stainless steel body

Reach hygienic standards, achieve high cleanliness and never deform to bring you a better experience in use;

Wide range of application

It is suitable for medicine, daily chemical, food and special industries, and is an ideal equipment for dual-purpose filling of liquid paste;

| Model | GCZKXG-30B |

| Voltage | 110v/220v 50-60HZ |

| Power | 1.2KW |

| Air pressure | 0.5-0.7 Mpa |

| Working capacity | 10-25 pcs/min |

| Bottle pressure | ≤67 KPA |

| Cap diameter | 20-100 mm |

| Bottle height | 50-200 mm |

| Machine dimension | 75*65*150cm |

| Machine weight | 220 kg |

The vacuum capping machine is mainly operated through the control panel, it is simple and easy to operate.

1.Open the vacuum capping machine “cap opening” knob;

2.Turn the adjustment knob to the leftmost (slowest) first, then turn off the power switch;

3.When shutting down the machine, turn the speed control knobs to the far left first;

Tips: The vacuum capping machine designs the corresponding mold according to the bottle specifications, and manually puts the bottle and takes the bottle manually, which is simple, convenient and fast, and can ensure the stability of the vacuum degree during the capping vacuuming process.

If you also interested in the vacuum capping machine glass jar, welcome to contact us to get 100% free quotation online freely!!

If you need our products please write down any questions, we will reply as soon as possible.