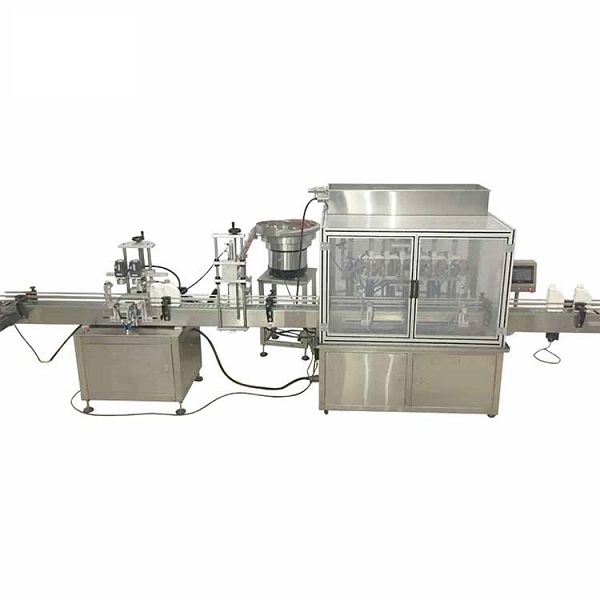

Multi-head fully automatic piston liquid filling machine has multiple filling heads(2 heads,4 heads,6 heads,8 heads, etc.), which can fill multiple containers at the same time, improving production efficiency.

Whatsapp:

+86 17838313979E-mail:

[email protected]Multi-head fully automatic piston liquid filling machine has multiple filling heads(2 heads,4 heads,6 heads,8 heads, etc.), which can fill multiple containers at the same time, improving production efficiency. The GT series is easy to maintain, has no bottles, no filling, accurate filling volume, and has a counting function. The industrial piston filling machine is an efficient filling equipment widely used in food, pharmaceutical, cosmetics, and other industries.

Anti-corrosion and anti-drip

Wide range of usage specifications

The production line is high-speed and efficient;

High-precision ceramic pump or stainless steel pump filling

Multiple rounds of capping overcome the shortcomings of multiple bottle caps and multiple capping heads

1. Suitable for packing different material cups.

2. Featured with automatic load cup, filling, and output into one with a high degree of automation.

3. GT4T-4G Automatic paste filling machine using PLC and man-machine interface control, the operation is simple and clear.

4. The filling accuracy is high, the electric eye automatically tracks and corrects the sealing position, and the sealing pattern is accurately aligned.

Here is the fully automatic piston filling machine youtube video working process in our factory for your reference!!

| Model | GT2T-2G | GT4T-4G | GT6T-6G |

| Voltage | 110V/220V 50HZ/60HZ 800W | ||

| Filling range | 5-100ML,10-280ML | 20-500ML,100-1000ML | 500-2800ML,1000-5000ML |

| Filling accuracy | 10-40bottles/min | 20-50bottles/min | 30-70bottles/min |

| Air pressure | ≤±1% | ||

| Filling speed | 0.5-0.7Mpa | ||

| Weight | 220kgs | 260kgs | 300kgs |

| Dimension | 210x86x146cm | 260x86x146cm | 320x86x146cm |

Stable: Using advanced control systems and sensors to ensure the filling process is stable and reliable.

Flexible: The equipment can be adjusted according to different container sizes and liquid types and is suitable for filling products of different specifications.

Precision: The equipment is equipped with a high-precision piston pump, which can accurately control the filling volume of liquid and ensure product quality.

Efficient: The multi-head design allows the equipment to fill multiple containers at the same time, which greatly improves production efficiency and is suitable for mass production.

Customizable automatic lidding system

Reduce labor and improve efficiency;

Cream and liquid dual-use

High silo design, can be equipped with automatic feeding system;

Multiple rounds of rubbing cover

Solve and overcome the shortcomings of various bottle caps and various capping heads;

PLC program-controlled fully automatic equipment

PLC program-controlled fully automatic equipment, touch screen operation, including safety and alarm functions;

High filling accuracy

Servo system PID control high-precision ceramic pump or stainless steel pump filling and liquid contact parts are imported custom silicone tubes/accuracy ≤ +0.5%;

Multi-head fully automatic piston liquid filling machine can be widely used for filling various liquid products, such as beverages, juices, cosmetics, detergents, etc. Its high efficiency, flexibility, stability, and accuracy make it an ideal choice for manufacturing companies to improve production efficiency and save costs.

If you are interested in a multi-head fully automatic piston liquid filling machine, we have a variety of models and specifications to choose from. Welcome to contact us, and we will provide you with more detailed product information and quotation.

If you need our products please write down any questions, we will reply as soon as possible.