How Does Gravure Printing Work

Gravure printing is a common printing technique widely used in packaging, labels, and magazines. It achieves the printing effect through the uneven layout and has the characteristics of high quality and high precision.

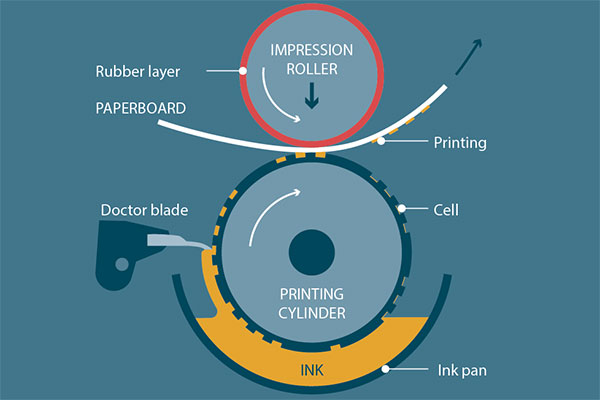

Gravure printing works by chemically etching an image or text onto a metal plate. This metal plate is usually made of copper or nickel and has a polished surface for smoothness. Then, apply ink on the plate, and scrape off the excess ink with a scraper, leaving only the ink to fill the grooves of the plate. Next, the printing material (such as paper or plastic film) is brought into contact with the plate, and the ink is transferred to the printing material by pressure to form an image or text.

One of the advantages of gravure printing is that it can achieve high-precision printing effects. Since the layout is made by chemical etching, very fine patterns and characters can be realized. This makes gravure printing the technology of choice in areas where high print quality is required, such as premium packaging and magazines.

In addition, gravure printing can also achieve a variety of special effects, such as a concave-convex feeling and metallic luster. By engraving grooves of different depths on the layout, it can produce tactile differences and increase the texture of the product. At the same time, through the use of special inks or coatings, the printed matter can have a metallic texture and increase visual appeal.

However, gravure printing also has some limitations. First of all, making gravure requires a certain amount of time and cost. Since the production process is relatively complicated and requires multiple processes, the plate-making cycle is relatively long. Second, gravure printing is only suitable for smaller printing quantities. Due to the high cost of plate making, the cost advantage of gravure printing is not obvious when it is suitable for large-scale printing.

In general, gravure printing is a high-quality, high-precision printing technology. It achieves the printing effect through the uneven layout and can achieve a variety of special effects. Despite some limitations, gravure printing still holds great promise in areas such as packaging, labels, and magazines.