LX6000 Aluminum foil sealing machine continuous induction sealer utilizes the magnetic induction principle to produce instant high heat to melt aluminum foil. Then it adheres to the bunghole, reaching the aim of being wet-proof, leakage-proof, mildew-proof, and extending preservation time.

Whatsapp:

+86 17838313979E-mail:

[email protected]The continuous electromagnetic induction sealing machine adopts the principle of electromagnetic induction heating and can effectively seal various plastic bottles, glass bottles, cans, and other containers to ensure the sealing and hygienic safety of the product. It is a packaging equipment widely used in food, medicine, daily chemicals, and other industries.

The continuous electromagnetic induction sealing machine adopts the electromagnetic field induction heating principle, which uses high-frequency current to generate a magnetic field through an inductor coil. When the magnetic field lines pass through the sealing aluminum foil material, a large number of small eddy currents are instantly generated, causing the aluminum foil to heat itself at high speed and melt the components compounded on the aluminum foil. Melt glue and stick it on the seal of the sealing material to achieve the purpose of rapid sealing. The material of the sealed container can be polyethylene (PE), poly(PP), polyester (PET), poly(PS), ABS, glass, etc. It cannot be used for metal bottles and caps. (The company also provides induction aluminum foil films of various materials).

Here is the continuous electromagnetic induction sealing machine YouTube video working process in our factory for your reference!!!

| Model | LX-6000 |

| Power Supply | AC 220V 50/60HZ |

| Input Power | more than 1200W |

| Output Power | less 600W |

| Ambient humidity | 10-40 degrees Celsius |

| Seal type | Continuous type |

| Sealing speed | 0-10 m/min |

| Seal diameter | 20-80mm |

| Height of bottle | 20-300mm |

| Bottle of diameter | 20-80mm |

| The total maximum load weight | less 3kg |

| Packing size | 950*620*470mm |

| Package weight | 50kg |

1. Air-cooled induction technology;

2. Advanced intelligence and complete functions;

3. Automatic and continuous, wide application range;

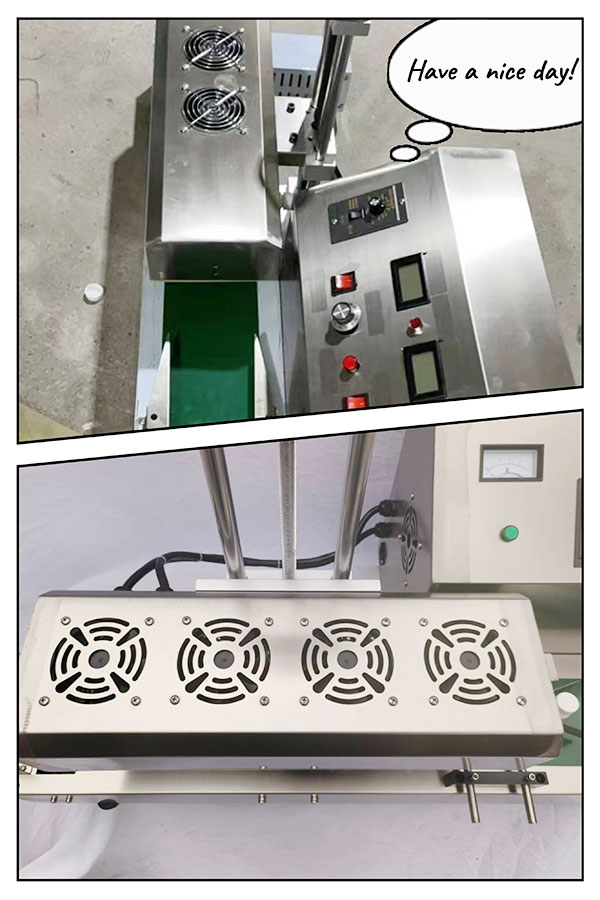

Control Panel

The panel is simple, simple to operate, and easy to use;

Thickened conveyor belt

The equipment uses thickened and wear-resistant conveyor belts, which are stable and durable;

Large heat sink

The equipment adopts large heat dissipation vents, which can dissipate heat more quickly;

Induction table height adjustment handle

Movable induction table height adjustment handle when using containers of different heights;

The feeding port is adjustable

The size of the feed port of the conveyor table is adjustable so that bottles of various diameters can be conveyed normally;

Pure copper induction coil

The sealing head composed of 4 pure copper induction coils has fast induction speed, firm sealing, stability, and efficiency;

Here is the automatic induction sealing machine youtube video testing machine for your reference!!

(1) Clean the inside and outside of the equipment. There is no oil on the sliding surfaces, screws, racks, gearboxes, oil holes, etc., and there is no oil or air leakage in all parts. The chips, debris, and dirt around the equipment should be cleaned. clean;

(2) Neatness: Tools, accessories, and workpieces (products) must be placed neatly, and pipes and lines must be organized;

(3) Good lubrication: refuel or change the oil on time, keep oiling, no dry friction, normal oil pressure, bright oil mark, smooth oil passage, oil quality meets requirements, oil, oil cup and linoleum are clean;

(4) Safety: Comply with safe operating procedures, do not overload equipment, have complete and reliable safety protection devices, and eliminate unsafe factors in a timely manner.

In summary, the continuous electromagnetic induction sealing machine, as an advanced packaging equipment, has the advantages of fast sealing speed, good sealing effect, and simple operation. It is widely used in food, medicine, daily chemicals, and other industries. With the continuous development and innovation of the packaging industry, it is believed that continuous electromagnetic induction sealing machines will have broader application prospects in the future.

If you need our products please write down any questions, we will reply as soon as possible.