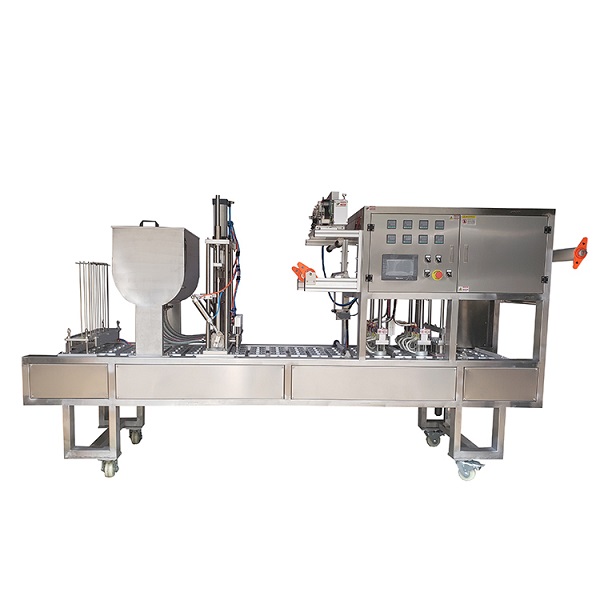

This YZH-300P-4 Assembly line filling and sealing machine is suitable for: milk tea, fruit juice drinks, carbonated drinks, alcoholic beverages, oils, hair care products, skincare products, cosmetics, cleaning products, yogurt, fresh milk, jelly, sauces, oral liquids. Equipped with liquid screen display and counting function, aluminum sealing cup ring, easy to clean, clean, and hygienic.

Whatsapp:

+86 17838313979E-mail:

[email protected]The automatic linear cup filling and sealing machine is an efficient packaging equipment that can fill and seal four cups/boxes at the same time. It can automatically complete unwinding, measuring, edge sealing, blanking, sealing, finished products, and fully automatic packaging, saving time and effort. This cup-filling and sealing machine is widely used in food, beverage, cosmetics, and other industries because it can improve production efficiency, reduce labor costs, and ensure product hygiene and quality.

Drip-proof filling;

Made of stainless steel;

Intelligent PLC control;

High-precision measurement;

Constant temperature heat sealing;

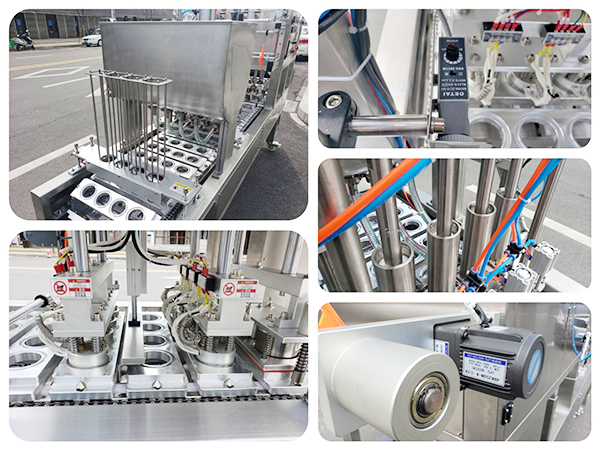

1. Using PLC and man-machine interface control, the operation is simple and clear.

2. Featured with automatic load cup, filling, sealing, and output into one with a high degree of automation.

3. The filling accuracy is high, the electric eye automatically tracks and corrects the sealing position, and the sealing pattern is accurately aligned.

4. The YZH-300P-4 Assembly line filling and sealing machine is made of high-quality 304 stainless steel and aluminum alloy, which meets GMP requirements.

Here is the automatic cup filling and sealing machine YouTube video working process in our factory for your reference!

| Model | YZH-300L-4 |

| Output | 1200-1800pcs/h (can be customized to different models) |

| Voltage | AC 220V / 50HZ |

| Power | 1750W |

| Mold | 1 time fill 4 cups |

| Capping film | Rotary film/ pre-cut lid |

| Film material | PE, PP, PET |

| Sealing temperature | 0-300℃ |

| Air Consumption | 0.6Mpa |

| Dimensions | According to customized capacity |

| Weight | According to customized capacity |

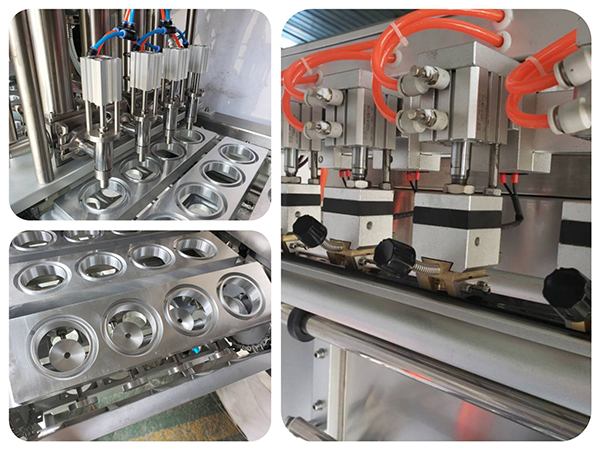

Filling device

Piston-type quantitative filling, accurate measurement, made of stainless steel to ensure food hygiene;

Sealing cylinder

Good anti-corrosion performance; good anti-corrosion performance; compensation function; low starting pressure;

Cup drop device

Intelligent electric eye detection, automatic cup dropping, optional large-capacity cup storage bin to improve work efficiency;

Pneumatic self-priming film

The film can be aligned and flat; the sealing is smooth and beautiful; manpower and material resources are reduced; the operation steps are simple

Film placing device

The electric eye tracks and corrects the film pattern and cup mouth position, and the vacuum suction cup automatically picks up and releases the film;

Sealing device

It adopts constant temperature (intelligent temperature control) hot pressure sealing, the sealing pressure is adjustable, and the sealing is tight and does not leak;

Overall, the automatic linear cup filling and sealing machine is an efficient, fast, hygienic, and flexible packaging equipment. It can greatly improve production efficiency, reduce labor costs, and ensure product quality and hygiene, so it has been widely used and favored. With the continuous advancement of science and technology, I believe that this kind of machine will be more widely used in the future and will be continuously improved and improved to provide better support and guarantee for production in all walks of life.

If you need our products please write down any questions, we will reply as soon as possible.